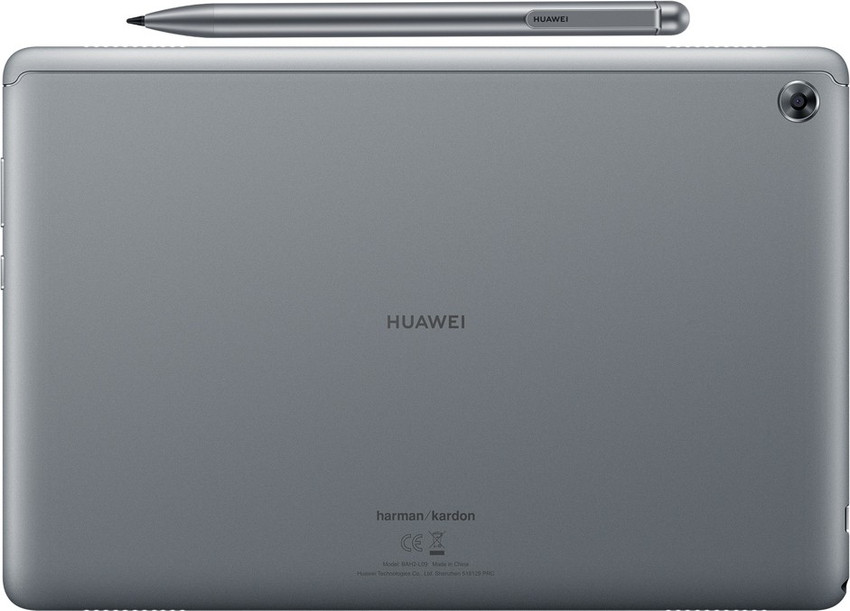

Amazon.com : Huawei MediaPad M5 Lite 10.1" Full HD Wi-Fi Tablet with Pen, Quad Stereo Speakers, Kirin 659, 3GB RAM, 32GB ROM, Android 8.0, 8MP FF/AF Camera, Space Gray : Electronics

Amazon.com : Huawei MediaPad M5 Lite 10.1" Full HD Wi-Fi Tablet with Pen, Quad Stereo Speakers, Kirin 659, 3GB RAM, 32GB ROM, Android 8.0, 8MP FF/AF Camera, Space Gray : Electronics

Amazon.com : Huawei MediaPad M5 lite - 10.1 inch - WiFi Only - 3GB+32GB Quad Harman Kardon-Tuned Speakers- Space Gray : Electronics

HUAWEI Tablette tactile MediaPad M5 Lite - 53010DJH - 10" - 3Go de RAM - Android 8.0 - Kirin 659 - Stockage 32Go - Wifi/4G - Cdiscount Informatique

Amazon.com : Huawei MediaPad M5 Lite 10.1" Full HD Wi-Fi Tablet with Pen, Quad Stereo Speakers, Kirin 659, 3GB RAM, 32GB ROM, Android 8.0, 8MP FF/AF Camera, Space Gray : Electronics

Huawei MediaPad M5 Lite with stylus 4 GB RAM 64 GB ROM 10.1 inch with Wi-Fi+4G Tablet (Space Grey) Price in India - Buy Huawei MediaPad M5 Lite with stylus 4 GB

HUAWEI MediaPad M5 Lite, 10.1in, 32GB, 3GB RAM, 4G (Gold): Buy Online at Best Price in Egypt - Souq is now Amazon.eg

Amazon.com : Huawei MediaPad M5 lite - 10.1 inch - WiFi Only - 3GB+32GB Quad Harman Kardon-Tuned Speakers- Space Gray : Electronics

Amazon.com : Huawei MediaPad M5 Lite 10.1" Full HD Wi-Fi Tablet with Pen, Quad Stereo Speakers, Kirin 659, 3GB RAM, 32GB ROM, Android 8.0, 8MP FF/AF Camera, Space Gray : Electronics

Amazon.com : Huawei MediaPad M5 lite - 10.1 inch - WiFi Only - 3GB+32GB Quad Harman Kardon-Tuned Speakers- Space Gray : Electronics

![Achat reconditionné Huawei MediaPad M5 Lite 10,1" 32 Go [Wifi] space gray| rebuy.Fr Achat reconditionné Huawei MediaPad M5 Lite 10,1" 32 Go [Wifi] space gray| rebuy.Fr](https://d1o0zx25fn5p70.cloudfront.net/Fh0I6uXAy8sOZ6kC2r3LB_ucwL0=/fit-in/350x350/noupscale/rebuy-akeneo/0/8/0/2/0802b9910be3f0e0d98fcc2dcf2ae955c6434d6f_frontcover_electronics_file_11013705.jpeg?t=1691654852)